Unlock the Secrets of 1.75mm ABS Filament: Heat Resistance That Redefines Your 3D Printing Experience!

In the world of 3D printing, the choice of filament can significantly impact the outcome of your projects. Among the various options available, 1.75mm ABS filament stands out for its versatility and reliability. One of the most notable features of this filament is its heat resistance, which is crucial for applications where temperature fluctuations are common. As more enthusiasts and professionals explore the potential of 3D printing, understanding the properties and advantages of 1.75mm ABS filament becomes increasingly important. Whether you're designing functional prototypes or artistic creations, knowing the benefits of heat-resistant filament can open new doors in your 3D printing journey.

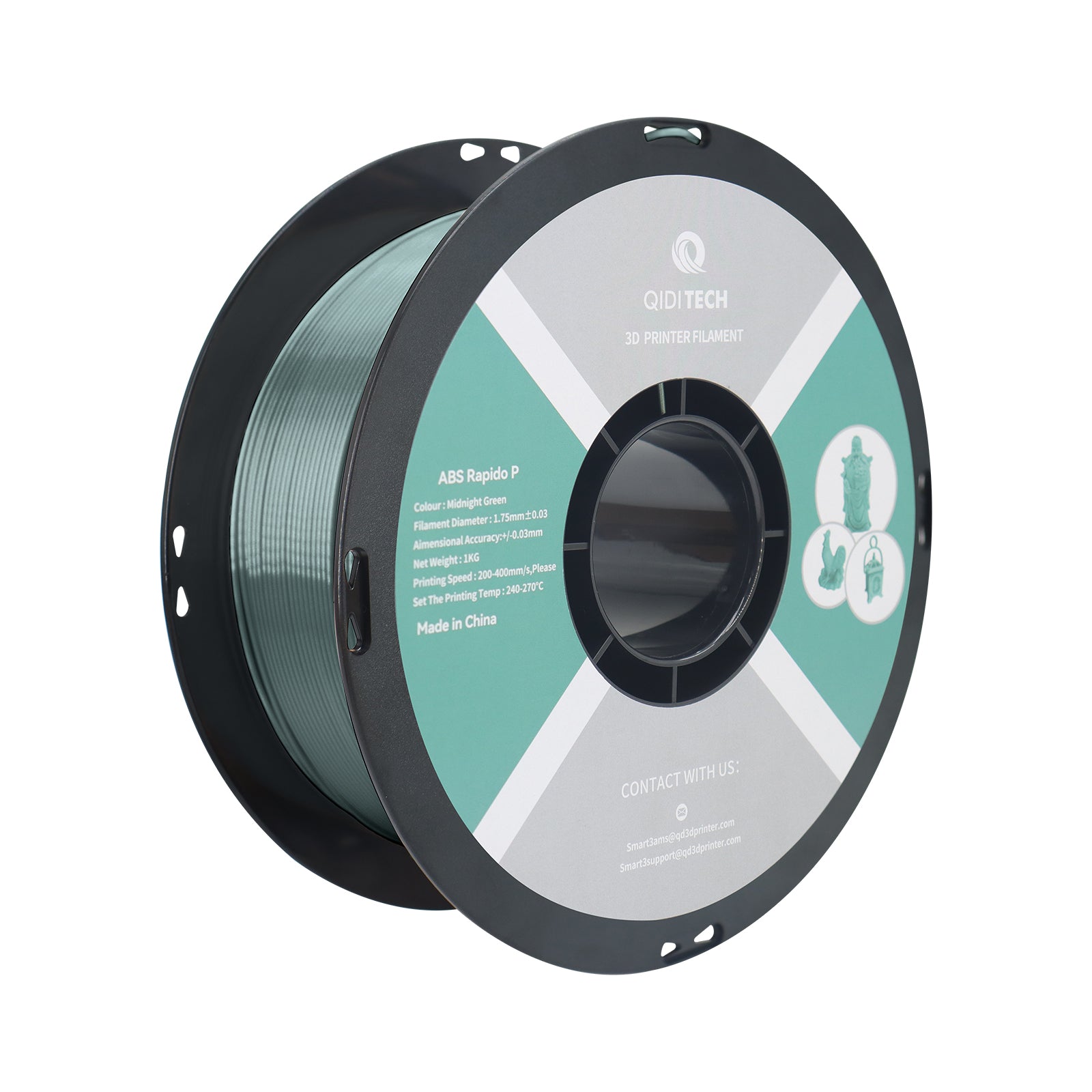

Understanding 1.75mm ABS Filament

1.75mm ABS filament is made from acrylonitrile butadiene styrene, a thermoplastic polymer known for its robustness and adaptability. The 1.75mm diameter is particularly favored among 3D printing enthusiasts due to its compatibility with a wide range of printers, especially those that use a Bowden extruder system. This diameter allows for precise extrusion and smoother flow, resulting in high-quality prints with minimal stringing and oozing. Additionally, ABS filament is known for its ability to withstand higher temperatures compared to other materials, making it an ideal choice for projects that require durability and heat resistance. Personal experiences from fellow hobbyists often highlight how the combination of ease of use and the dependable properties of 1.75mm ABS filament contributes to successful print results.

Key Properties of 1.75mm ABS Filament

The physical properties of 1.75mm ABS filament are what truly set it apart from other common filaments like PLA or PETG. ABS is known for its excellent strength and impact resistance, enabling it to withstand significant force without fracturing. This makes it an ideal choice for functional parts that must endure wear and tear. Additionally, ABS exhibits a certain level of flexibility, allowing it to bend under pressure without breaking. When compared to PLA, which is more brittle, ABS provides a much more resilient option for projects requiring durability. Friends who have transitioned from PLA to ABS have noted a marked improvement in the longevity of their prints, especially in applications like toys and automotive parts where robustness is essential.

Heat Resistance: A Game Changer for 3D Printing

Heat resistance is a critical characteristic for many 3D printing applications, especially in industries such as automotive and electronics. Components exposed to high temperatures must be made from materials that can tolerate heat without deformation. 1.75mm ABS filament excels in this regard, offering thermal stability that ensures prints maintain their shape and functionality even when subjected to heat. For instance, in automotive prototyping, parts made from ABS can withstand the warm temperatures found under the hood without warping. Moreover, in the realm of electronics, the filament's ability to handle heat makes it suitable for creating housings for devices that generate warmth. Stories from users who have successfully printed heat-resistant components illustrate how 1.75mm ABS filament can redefine the capabilities and applications of 3D printing.

Benefits of Using 1.75mm ABS Filament with Good Heat Resistance

Choosing 1.75mm ABS filament with good heat resistance offers numerous advantages, making it an excellent choice for various projects. One of the primary benefits is its durability; ABS is less likely to crack or break under stress, allowing for long-lasting prints. Furthermore, the versatility of ABS means it can be used for everything from prototypes to functional parts, catering to a wide range of user needs. Additionally, the ease of use associated with this filament enhances the overall 3D printing experience. Many users report that the filament adheres well to build surfaces, and with the right settings, it can produce stunning, high-quality prints. Having friends share their experiences of switching to ABS has highlighted how this material can elevate the quality and functionality of their projects.

Tips for Printing with 1.75mm ABS Filament

To achieve optimal results when printing with 1.75mm ABS filament, it’s essential to follow a few practical tips. First, maintaining a consistent printing temperature is crucial; a nozzle temperature between 210°C and 250°C is typically recommended. Bed adhesion can also be a challenge with ABS, so using a heated bed set to around 100°C can help minimize warping. Additionally, employing techniques like the use of an enclosure can further stabilize the print environment, reducing the risk of cracking or warping. Post-processing methods such as sanding or acetone vapor smoothing can enhance the finish of your prints, making them more visually appealing. Friends who have adopted these practices consistently report improved print quality and a more enjoyable printing experience.

Elevate Your 3D Printing with 1.75mm ABS Filament

In summary, 1.75mm ABS filament with good heat resistance is a powerful tool for anyone looking to elevate their 3D printing projects. Its unique properties, including strength, flexibility, and thermal stability, make it suitable for a wide range of applications, from functional prototypes to decorative items. The benefits of using this filament, such as durability and ease of use, further enhance the 3D printing experience. As you consider your next project, think about the potential of 1.75mm ABS filament to meet your needs and exceed your expectations. Embrace the possibilities this material offers and take your 3D printing journey to new heights!