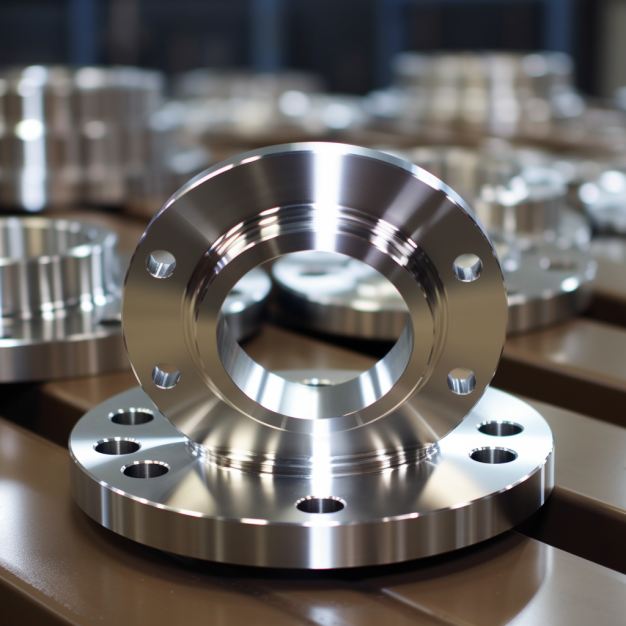

Flanges are critical components for reliably joining pipe sections and components in pipelines. However, with various pipe flanges types available, understanding their characteristics is important for proper selection and use. This article defines flanges and examines their common types, materials, and classifications.

Definition of a Flange

A flange is a projecting rim, collar or edge usually found at the end of pipes, valves or vessels. Flanges allow connections to be easily assembled and disassembled for inspection, maintenance or repair work via bolted connections.

Common Flange Types

Popular flange types used in pipelines include:

- Slip-on flanges

- Weld neck flanges

- Socket weld flanges

- Threaded flanges

- Blind flanges

- Lap joint flanges

Each flange type and pipe flanges types suit different pressure levels, temperatures, installation locations and budgets.

Flange Materials

Common materials used for plumbing flange types include carbon steel, alloy steel, stainless steel, cast iron, aluminum and brass. Material selection depends on medium conveyed and corrosion resistance required.

Flange Face Types

Flanges feature faces that can be flat, raised face, ring type joint (RTJ) or tongue and groove. Faces affect sealing capability and joint strength.

Flange Standards

Design and dimensions of pipe langes types are specified by standards like ANSI, DIN, ISO, JIS for consistent dimensions worldwide.

Selection Guidance

Reference guides and consult standards to determine the best flange type optimized for your pipeline's pressure, temperature, medium, location needs and budget.